Today, in order not to damage them, olives are harvested directly from the tree using mechanical shakers or beaters, or by hand-stripping the branches.

This operation is carried out when the olives have reached the right level of ripeness, which is indicated by the typically greenish violet colouration process referred to as veraison.

This operation is carried out when the olives have reached the right level of ripeness, which is indicated by the typically greenish violet colouration process referred to as veraison.

The olives are placed in aerated trays and transported as soon as possible to the oil mill to be processed – the processing usually takes place on the very day the olives are picked, thanks to the large capacity of our continuous-cycle milling machinery.

Processing cycle

Our mill uses a continuous system, whereby the various phases (washing the olives, separating the oil from the water) are executed automatically, with no requirement for human intervention. The processing operation passes through the following phases:

- Leaf removal

- Weighing

- Storage in trays

- Washing

- Crushing

- Grinding

- Pressing

- Separation

- Storage in tanks

- Bottling

After leaf removal and weighing,

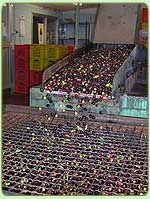

After leaf removal and weighing,  the olives are transported along a conveyor belt to the washing machinery, which cleans them thoroughly and removes any residual leaves.

the olives are transported along a conveyor belt to the washing machinery, which cleans them thoroughly and removes any residual leaves.

Once the olives have been washed, they are crushed in a cylindrical crusher before entering the grinder, which – by mixing the olives and breaking up the emulsions that form between the oil and  water – grinds them to a paste. The olive paste is then pressed, using centrifugal extractors that separate the heavier particles (solids) from those with a lower specific weight (liquid).

water – grinds them to a paste. The olive paste is then pressed, using centrifugal extractors that separate the heavier particles (solids) from those with a lower specific weight (liquid).

After pressing, the solids pass through a screw filterwhereas the liquid passes  through centrifugal separators that separate the oil from the vegetation water. Using suitable receptacles, the oil undergoes racking and is deposited into one of five tanks (one with a capacity of 1700 litres, one 5000-litre tank and three 500-litre tanks).

through centrifugal separators that separate the oil from the vegetation water. Using suitable receptacles, the oil undergoes racking and is deposited into one of five tanks (one with a capacity of 1700 litres, one 5000-litre tank and three 500-litre tanks).

Quantities of oil are then removed from the stainless-steel tanks for the filtering and bottling stages, after which the oil is packaged to make it ready for sale. The finished oil successfully combines a slight (intentional) bitterness with an aftertaste of artichokes. It is at its best used raw to enrich an infinite variety of dishes with its fruity fragrance.

Quantities of oil are then removed from the stainless-steel tanks for the filtering and bottling stages, after which the oil is packaged to make it ready for sale. The finished oil successfully combines a slight (intentional) bitterness with an aftertaste of artichokes. It is at its best used raw to enrich an infinite variety of dishes with its fruity fragrance.